Note: In order to avoid personal injury and man-made damage, the maintenance of the handheld laser cleaning machine must be carried out by professionals.

1.Handheld cleaning head (Upgrade Cleaning Head, Continuous Operation without Burning the Lens)

1.1 Daily inspection: Check the protective lens. If there is foreign matter, use a special dust-free cotton swab dipped in industrial alcohol to clean it. If there is coating damage or lens damage, please replace the protective lens in time to avoid other optical lenses being burned.

1.2 Regular inspection: When the machine is used or not used for some time, first check the laser module, and make sure that each optical component is free from dust pollution, mildew, and other abnormal phenomena before turning it on.

1.3 Observing the light spot: The operator can check the laser output light spot with black image paper. Once the spot is found to be uneven or skewed, it should be repaired in time.

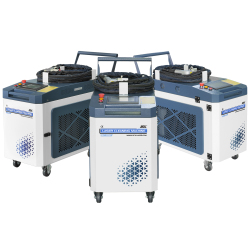

2.Water chiller

2.1 The dust on the condenser and the dust filter needs to be cleaned regularly.

2.2 When the machine is transported or not used for a long time, the coolant should be drained.

2.3 When the temperature is lower than 2°C, please check and ensure that the chiller is working properly before using the machine to avoid damaging the laser tube, output head, and water chiller due to the solidification of the coolant.

2.4 The coolant must be replaced in the following cases

2.4.1 The filter element has been replaced.

2.4.2 After 3 months of use.

2.4.3 Use again after long-term non-use

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Leave A Comment