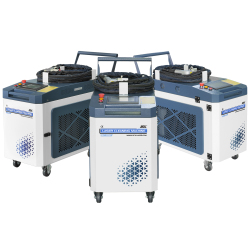

The laser cleaning technology has opened up a new field of industrial application of laser technology.

It is used in microelectronics, construction, power stations, automobile manufacturing, medical care, cultural relics protection and other fields, especially in steel rust removal and mold decontamination.

1. Product molds: tire molds, rubber molds, injection molds, etc.

As a high-precision mold application in the mold industry. This type of cleaning is mainly a precision type commonly used pulse laser cleaning machine.

2. Construction engineering: excavation machinery, shovel transportation machinery, compaction machinery, engineering hoisting machinery, pile machinery, road machinery, concrete machinery, etc.

Large-scale construction and construction machinery have been exposed to the sun and rain outdoors for a long time and rust is more serious. The commonly used rust removal methods sand blasting and shot blasting are prohibited due to the huge pollution of these processes at the current stage of environmental protection; the environmental protection scheme of laser cleaning is highlighted . Construction machinery is widely distributed.

3. Electric power plants: thermal power, nuclear power, wind power.

The peripheral equipment and security settings of thermal power, nuclear power, and wind power will encounter cleaning situations. Continuous laser cleaning machines are commonly used for such large-scale equipment. They are mainly used for rust removal, paint, protective coatings, etc., with low precision requirements but large area and focus on efficiency.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Leave A Comment