As we all know, cutting machines like laser cutting machine, flame cutting machine, plasma cutting machine will have slag residue on the sword fence when working, all need to be cleaned up after a long time.

Laser cutting machines generally have a protective gas, commonly used protective gases are oxygen, nitrogen, compressed air. They produce different slag, oxygen generated slag is the easiest one to cleaned up, followed by nitrogen, air generated slag is the most difficult to clean.

Different power laser cutting machine have different cutting ability, and the slag produced is not the same, small power is granular, high-powered is lumpy.

If not clear slag in time, the cutting effect will be affected greatly.

Then how to choose the right model?

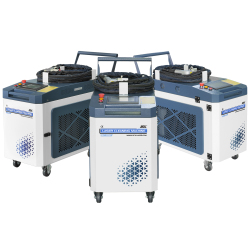

SFX offers two models laser slat cleaning machine, JS-1000 and JS-2300 laser slat cleaner. Suitable for sword fence thickness 3-8mm, suitable for fence rack minimum spacing of 30mm.

Equipment below 6000W, JS-1000 laser slat cleaner is OK. When oxygen, nitrogen as a protective gas, slag cleaning is very easy. Compressed air as a protective gas, the slag has formed a slag layer on the side, this situation is more difficult to clean up.

6000W-15000W laser cutting equipment, slag can not accumulate too thick, generally every 3-5 days to clean up once. If a thicker slag has been generated, it is recommended to clean up once every 3-5 days after replacing the sword fence. Need to use the JS-2300 model laser slat cleaner.

We offer 1 year warranty for SFX laser slat cleaning machine. Free shipping to your door by UPS/DHL/Fedex about 7-15 days. CE Certificate. Hot sale now in 80+ countries.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Leave A Comment