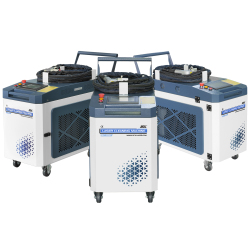

In the realm of laser cutting, maintaining the cleanliness of slats is paramount for ensuring optimal performance and longevity of equipment. With the advent of innovative solutions like the SFX Laser Slat Cleaning Machines, manufacturers now have access to advanced technology that streamlines the cleaning process, thereby enhancing productivity and efficiency. In this blog post, we delve into the features and benefits of two prominent models: the JS-1000 and JS-2300, tailored for different laser cutting machine specifications.

JS-1000 laser slat cleaner: Optimized for Laser Cutting Machines Below 6KW

The JS-1000 stands as a robust solution designed specifically for laser cutting machines with power ratings below 6KW. Its precision-engineered design enables efficient removal of debris, slag, and contaminants from slats, ensuring uninterrupted workflow and pristine cutting quality.

JS-2300 laser slat cleaner: Tailored for Laser Cutting Machines Between 6KW-15KW

For laser cutting machines operating within the 6KW to 15KW power range, the JS-2300 emerges as the ideal choice for slat cleaning requirements. Engineered with superior performance capabilities, this model offers unparalleled cleaning precision and speed, catering to the demands of high-power laser cutting operations. By effectively removing accumulated residues and maintaining slat integrity, it contributes to prolonged equipment lifespan and reduced maintenance costs, thus optimizing overall operational efficiency.

In the competitive landscape of laser cutting, optimizing operational efficiency is paramount for achieving sustained growth and success. The adoption of SFX Laser Slat Cleaning Machines, exemplified by the JS-1000 and JS-2300 models, represents a strategic investment for manufacturers seeking to streamline their cleaning processes and maximize productivity. By leveraging cutting-edge technology and innovative design, these solutions offer a compelling proposition for enhancing cutting quality, minimizing downtime, and ultimately driving profitability in laser cutting operations.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Leave A Comment