When searching for a laser cleaning machine, you may have two options, continuous laser cleaning machine (CW laser cleaner) and pulse laser cleaning machine. Do you know how to choose the right one?

Both continuous laser cleaning machine and pulsed laser cleaning machine can remove rust or paint on the surface of materials to achieve the effect of cleaning.

Under the same power conditions, the cleaning efficiency of pulsed laser cleaner is much higher than that of continuous laser cleaner. At the same time, pulsed laser can better control the heat input to prevent the substrate temperature from being too high or micro-melting.

Continuous laser cleaner has advantage in price, and can make up for the gap in efficiency with pulsed lasers by using high-power lasers, but high-power continuous laser cleaner has greater heat input and increased damage to the substrate.

Therefore, there are fundamental differences between the two in application scenarios.

With high precision, it is necessary to strictly control the heating of the substrate, and the application scenarios that require the substrate to be non-destructive, such as molds cleaning, should choose a pulsed fiber laser cleaner.

For some large steel structures, pipes, etc., due to the large volume and fast heat dissipation, the requirements for damage to the substrate are not high, and continuous fiber laser cleaner can be selected.

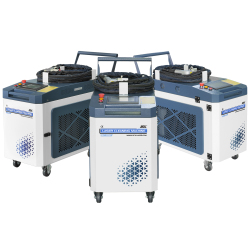

Continuous laser cleaning machine:1000W 2000W 3000W Continuous Laser Cleaning Machine

Pulse laser cleaning machine: Trolley-type 200W Pulse Laser Cleaning Machine, 300W 500W Pulse Laser Cleaning Machine,

100W Backpack Laser Cleaning Machine, 200W 300W 500W Platform Laser Cleaning Machine

Welcome to inquiry for more information.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Leave A Comment